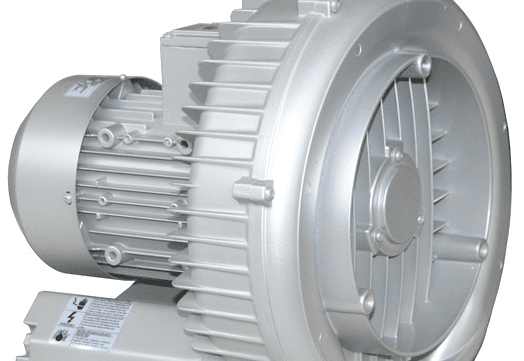

Controlling noise levels in the industry is a constant concern to protect employees and create a safe working environment. For example, the noise level in industrial pumps is about 110 dB (A), but to comply with noise regulations at work, it is required to reduce it to 75 dB (A) at a distance of one meter.

Elements Needed for a Complete Pump Noise Control Solution

There are usually several elements that collectively make up an effective pump noise control solution. Vibration isolation mounts help structural control noise transmitted from the high-powered motor and resonance through the enclosure. A custom acoustic structure is designed for the pump specific in terms of volume and noise output, using acoustic wall panels and ceilings to form a modular enclosure. Soundproof doors and windows to provide access for maintenance and monitoring purposes. More entries can be added for repair or replacement with large removable panels and access hatches without compromising the acoustic integrity of the structure. All internal surfaces must be absorbent to control any echo build-up, which in turn prevents the chance of the source noise level increasing resulting in a higher than the expected external noise level.

Ventilation and safety systems are an essential part of the pump system and must be effectively integrated into the acoustic enclosure design. The ventilation system is vital to the effective functioning of the pump – it provides airflow through the enclosure to cool the pump assembly and maintains the optimum operating temperature through the silencers and suction fans. Integrated safety systems include mission, emergency lighting, and fire suppression systems – with detailed integration into the acoustic enclosure and back to the mast control panel.

The complete condition must be tested and certified according to BS EN ISO 11546-2:2009 to ensure the pump assembly is operating; It will reach 75 dB (A) at a distance of one meter as indicated. There are several factors to consider when connecting a pump noise source that has both operational performance and safety implications – all of this need to work in synergy, requiring in-depth engineering knowledge and acoustic knowledge to ensure a high-quality level of performance.

Hodgson Acoustics has extensive experience in noise control enclosures for all noise source equipment, including pumps, compressors, fans, generators, and other heavy machinery.

Guide to Industrial soundproofing

There can be many reasons to keep the sound levels within a reasonable range in any work environment. However, proper levels above this range are seen as “noise.” Noise can distract the workforce, creating the unsafe workplace. Or worse yet, it can cause the hearing loss.

Need of Industrial Soundproofing

A worker; distracted by the noise may become less productive and even irritable. If noise levels are too high, the worker may not be able to hear warning signals or instructions. High noise levels over long periods can lead to permanent hearing loss. When any of these conditions exist, it is essential to control, contain, reduce or eliminate the noise source to maintain a safe working environment.

Basics of Noise Generations

The reader needs to know a few basics to understand how noise levels are controlled. For a noise problem, there must be a noise source, a noise propagating path, and a noise receiver. If these three elements are missing, there can be no noise or sound. This gives us an idea of how to control noise problems. By manipulating any component or combination of the three elements needed for noise or by implementing other industrial soundproofing measures, we can handle it. For example, a noise source such as a coarse generator can be made quieter by tuning it (source processing). In addition, a barrier can be placed between the generator and the receiver so that sound waves do not propagate to the receiver (path processing). Finally, the receiver (human ear) can be treated with earplugs or a headset (receiver processing). Often a noise solution must be designed to determine the most cost-effective and safe method that allows production to continue with minimal interference.

Discussion about this post